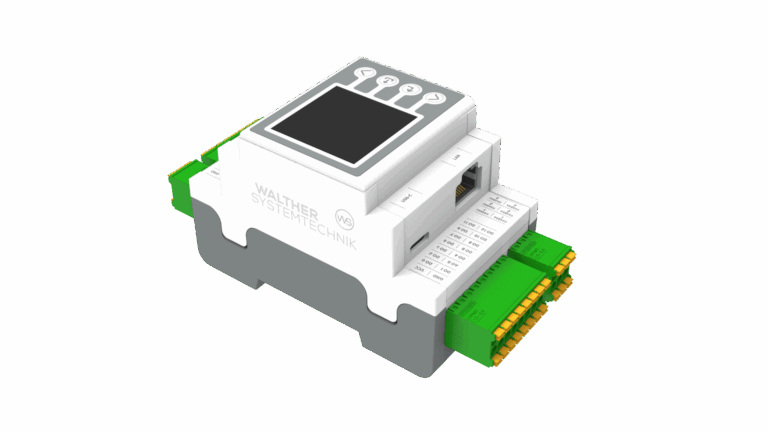

The WSV is an electric spray valve for the reliable application of media ranging from low to high viscosity. With its compact design (134.5 × 25 × 45 mm) and integrated electronics, it can be embedded directly into new or existing production systems without additional control hardware. Via an Ethernet-based bus connection, all process data can be fully configured and visualised using a web-based dashboard.

Features include four digital inputs/outputs for controlling peripheral devices, an optional valve heating unit with temperature regulation and – in the Professional version – a pressure sensor for monitoring the process pressure profile. An integrated push button allows manual triggering to check the spray pattern, simplifying commissioning and maintenance.

The WSV offers real-time monitoring and documentation of key process parameters. Remote configuration and diagnostics via the web interface enable efficient fault detection. Alarms and messages can be freely configured and linked to specific process values. This enhances process capability, overall equipment effectiveness (OEE) and product quality.

Compared with pneumatic or hydraulic solutions, the electric actuation of the WSV provides highly precise control with reduced energy consumption. This results in significantly lower operating costs, particularly in energy-intensive applications.

The three versions BASIC, ADVANCED and PROFESSIONAL covers different requirements. All variants share identical dimensions and can be easily integrated into systems thanks to their modular design. Replaceable components reduce maintenance costs and downtime. Add-ons such as Ethernet bus, needle stroke monitoring or multi-parameter sets, as well as firmware updates, extend functionality and keep the WSV spray valve up to date.