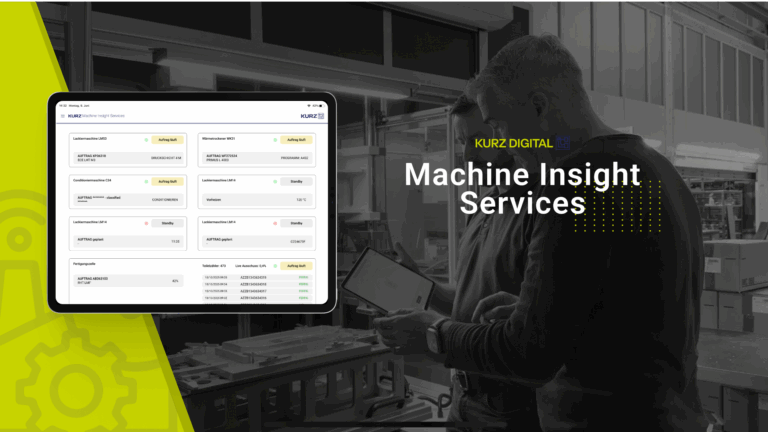

Our AI-powered process data analysis helps you identify planned and actual values, production weaknesses, bottlenecks, and quality deviations just-in-time. By creating a digital twin of your components, you can evaluate their condition in real time, automatically detect deviations, and analyze their root causes. At the touch of a button, you can identify your production limits, the transitions between good and defective parts, and thus the parameters for 100% quality and 0% rejects.

All the advantages at a glance:

– AI-powered quality predictions and anomaly detection in real time

– Reduction of scrap and rework through early error detection

– Stable processes through transparent production limits

– Higher product quality through data-driven decisions

– Breaking down data silos

– Flexibly adaptable to your systems and processes

– Elimination of time-consuming manual evaluations through digital shop floor management

More information: www.kurzdigital.com