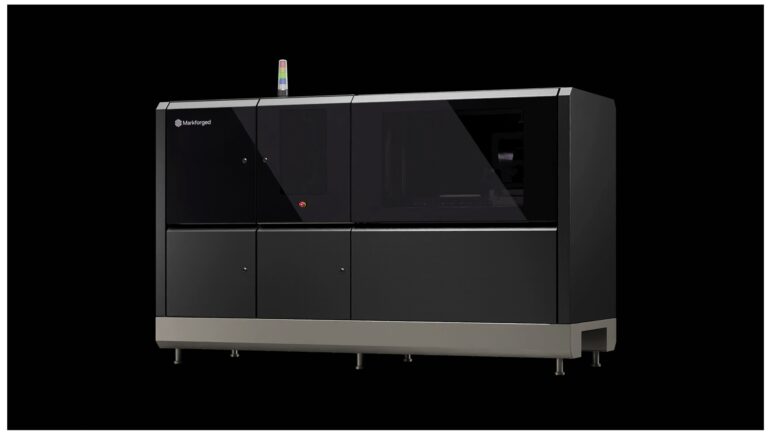

The X7 is the flagship of the Markforged Industrial series and delivers high-strength, precise components for daily use in production. With its sturdy aluminum frame, enclosed build chamber, and integrated laser measurement, it is designed for maximum repeatability and reliability – whether for single pieces or small series.

What’s special about the X7: It processes technical materials such as Onyx – a nylon reinforced with microcarbon fibers – and, if necessary, inserts continuous fibers such as carbon, Kevlar, or fiberglass directly into the components. This creates components with a strength that rivals aluminum – ideal for grippers, fixtures, equipment, or series components.

Using the Eiger software, print jobs can be prepared in just a few minutes, materials assigned, and fiber alignment precisely adjusted. Automatic calibration and an integrated laser scanner with 50 μm accuracy ensure that every component precisely meets the specifications.

Key Features:

Build volume: 330 x 270 x 200 mm

Materials: Onyx, Onyx FR, Onyx ESD, Smooth TPU 95A

Continuous fibers: Carbon, Kevlar, HSHT fiberglass, fiberglass

Integrated laser scanner for quality assurance

Automatic calibration and easy operation

The X7 has proven itself in continuous industrial use for years – in both SMEs and large corporations. Anyone looking to manufacture robust, functional components in-house with minimal effort will find the X7 a reliable choice.