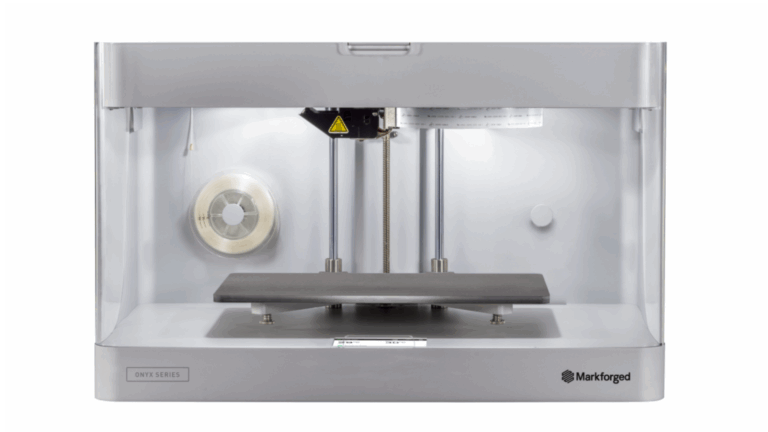

The compact entry-level model for industrial continuous fiber reinforcement – strong, precise, and proven

The Mark Two is the workhorse among Markforged’s desktop printers – compact in size, powerful in performance. It combines precise industrial 3D printing with the ability to massively reinforce components using integrated continuous fibers. This creates components that not only look like plastic but also behave like metal.

Printing is primarily done with Onyx, a nylon reinforced with microcarbon fibers that is characterized by high stiffness, dimensional stability, and a sophisticated matte surface. For areas subject to particularly high stress, continuous fibers such as carbon, Kevlar, or fiberglass can be inserted directly into the components – automated, layer by layer, precisely where the load is applied.

With its open yet protected build volume and intuitive Eiger software, the Mark Two is ideal for anyone looking to produce prototype-quality industrial components or fully functional equipment, fixtures, and spare parts in-house – without the need for a production shop.

Key Features:

Build Volume: 320 x 132 x 154 mm

Materials: Onyx, Onyx FR, Smooth TPU 95A

Continuous Fibers: Carbon, Kevlar, Glass Fiber, HSHT Glass Fiber

Compact Desktop Printer with Industrial Precision

Ideal for Development, Workshop, and Production-Level Environments

The Mark Two is a proven entry-level printer into the world of fiber-reinforced additive manufacturing – for anyone looking to print real components, not just models.