The lubrication of technical components is a key process step that directly affects functionality, service life, and product quality. It must be accurate, efficient, and repeatable – even in variant-rich production or under tight cycle times. This is exactly where ReadyLube comes in: a standardized, compact dispensing unit that combines technical precision with seamless integration.

ReadyLube is ready for use with minimal installation effort: simply connect the medium supply and compressed air – no additional commissioning required. The unit can be directly integrated into existing workstations or assembly lines. Lubrication is component-specific: either via a custom-designed application head or a precisely fitting part holder, ensuring exact, operator-independent application. Quick-change application heads allow ReadyLube to handle different part series with ease – a clear benefit for changing variants or small batch production.

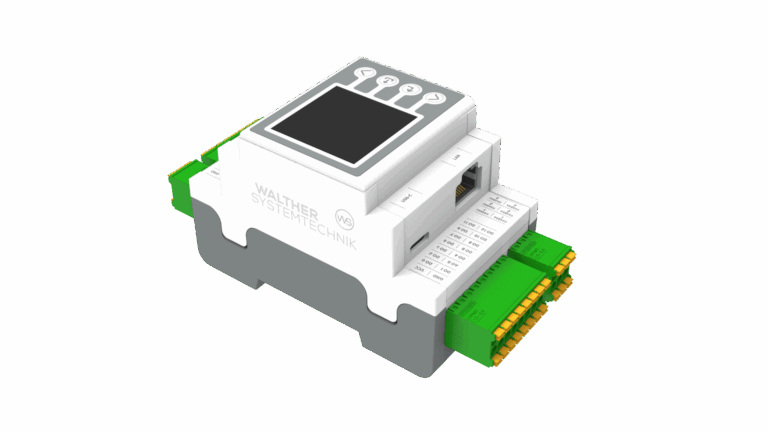

The BASIC version enables immediate operation with automatic activation via part contact. The ADVANCED version adds extended control and integration options: process monitoring with visual status indication, digital interfaces (3 outputs, 1 input), and flexible start options – either manual or via external control signals. This ensures smooth integration into higher-level control systems and sequence-controlled production lines.

Users benefit from a stable, standardized lubrication process, reduced downtime, and lower lubricant consumption. ReadyLube provides an economical alternative to manual or complex custom solutions – process-reliable, flexible, and ideal for modern production environments.