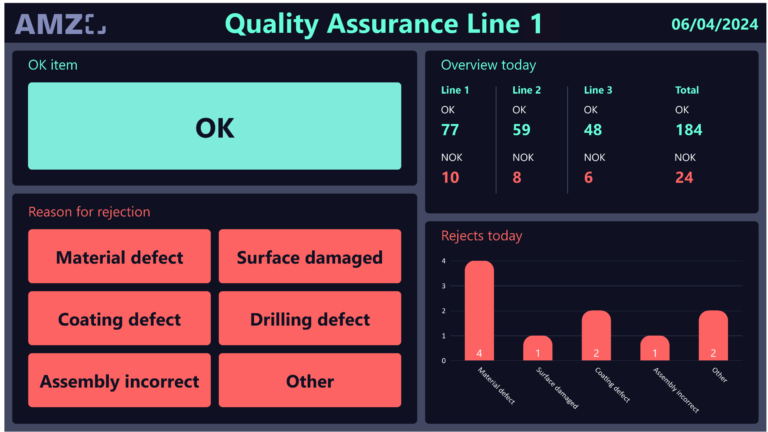

Inefficient assembly processes and frequent errors lead to production delays and quality problems. There is often a lack of clear guidance and support for workers to perform their tasks efficiently. Lack of visibility into the progress of assembly jobs makes it difficult to effectively manage production flow and identify bottlenecks early. Overcoming these challenges requires a worker assistance system that provides clear guidance, real-time feedback, and comprehensive monitoring of assembly processes. Peakboard’s interactive dashboard provides your workers with all the information and guidance they need to complete assembly jobs accurately and error-free. By combining descriptive texts, images, technical drawings and material lists, the assembly steps are visualized in a clear and understandable way. The system also records important parameters during the assembly process to enable real-time monitoring and evaluation. This includes, for example, recording the time required and counting the OK and NOK parts at the end of assembly. In addition, you can directly reorder the required materials in the internal warehouse logistics or, if necessary, report problems to production managers to reduce waiting times.