Drive Technology & Accessories for Cabinet-Builders

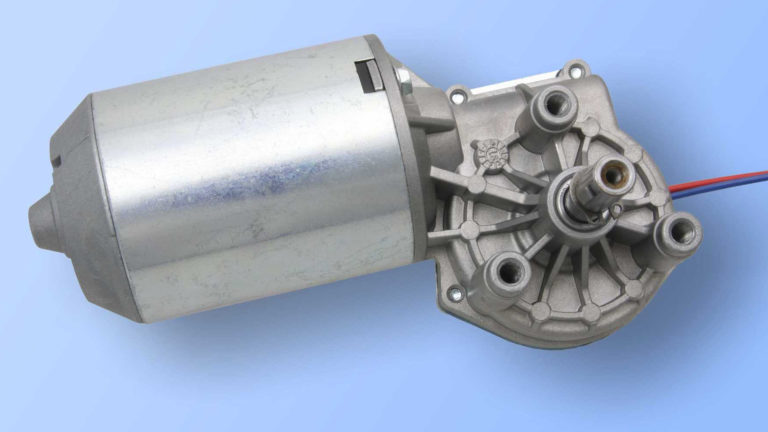

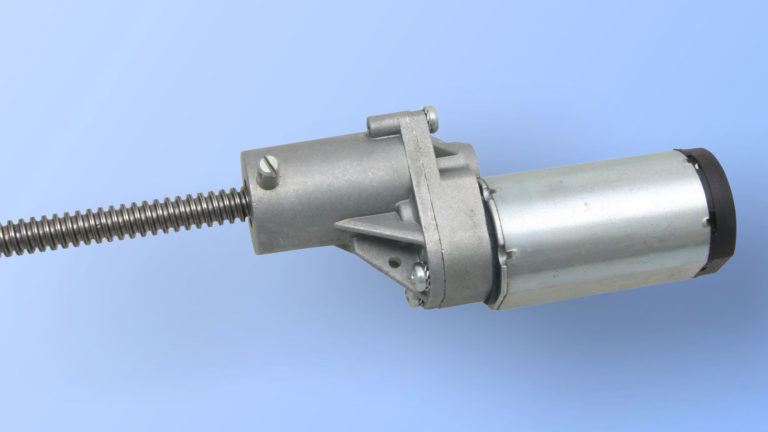

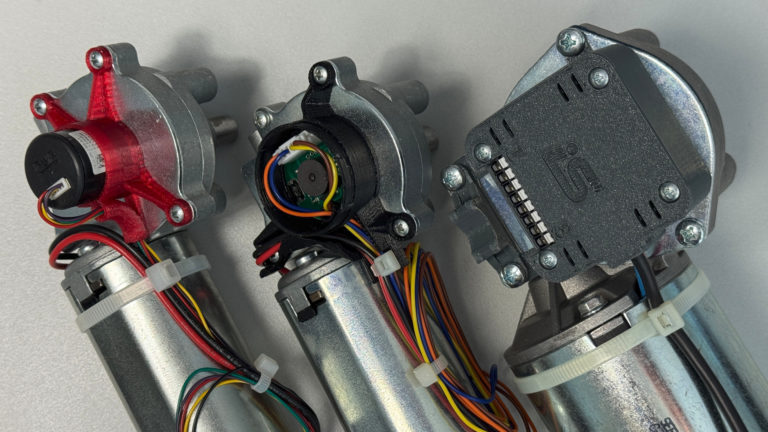

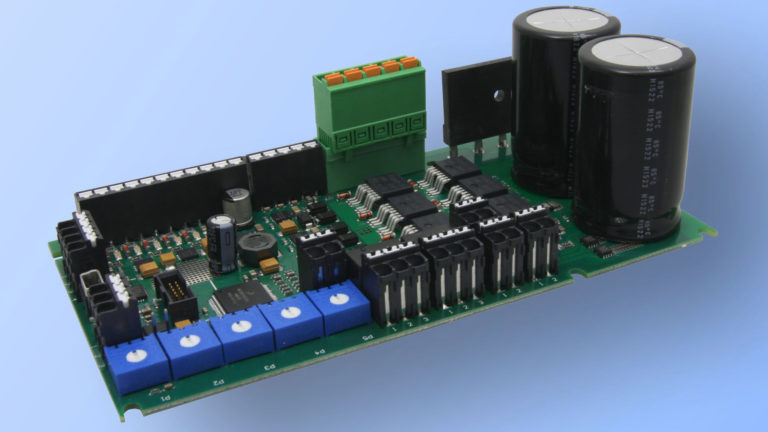

For over 30 years, Gerdt Seefrid GmbH, a specialist in DC/BLDC drive technology, has been offering a wide range of robust low-voltage motors, linear drives, intelligent motor controllers, and accessories. 36 series are available, including gearless motors and those with spur, planetary, and worm gears, in BLDC and brushed versions. In addition to the catalog range, drives and motor controllers can be offered customized to customer specifications, within the limits of manufacturing capabilities. Seefrid places great emphasis on high product availability and a good price/performance ratio. The majority of drives and most motor controllers are stocked in the large and well-stocked warehouse in Bad Vilbel and can be delivered at short notice.

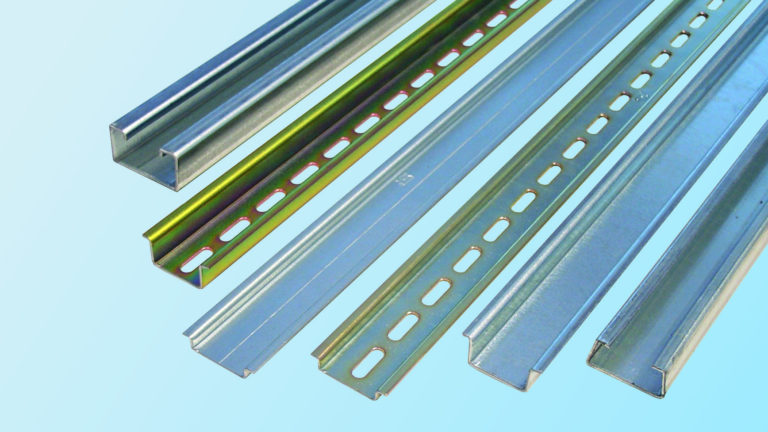

Another division of Gerdt Seefrid GmbH is the production of accessories for Cabinet-Builders and switchgear construction. With an extensive range of support and anchor rails, Gerdt Seefrid GmbH has established itself for many years as a reliable specialist supplier for control and switchgear construction.

The product range focuses on 25 different profile shapes, including the frequently used support rails 35×7.5 and 35×15 mm, as well as anchor rails in the dimensions 35×18 and 40×22 mm. The individual profile types are available with various hole sizes, hole shapes, and grid dimensions, as well as in unperforated versions. Depending on the profile type, customers can choose between Sendzimir and hot-dip galvanizing, as well as thick-film passivation. Profiles are also available in bright steel and copper. In total, there are over 80 different combinations, so that users can find the right profile for their application from a single source at Seefrid, directly from stock.

The product range is rounded out by mounting accessories that perfectly match the profiles, such as sliding nuts, hammer-head bolts, flat and diagonal clamps, grounding cables, and flat earthing strips.

Seefrid’s service offerings are a real highlight. For example, the cutting and punching service for profile rails enables cost savings, especially for medium and large quantities. Customers receive their profile rails cut to the desired length according to their drawings and, if necessary, punched. This is made possible by a dedicated machine park directly attached to the modern shipping warehouse.

Since its founding in 1949, Gerdt Seefrid GmbH has been active in the distribution of electromechanical components. Initially based in Bad Homburg, the headquarters moved first to Frankfurt, then Eschborn, and finally to its current location in Bad Vilbel in 1993.

The sales team is available to customers by phone, email, video conference, and is also happy to assist in person on-site.